Prescribed by your dental professional, Aligner zone are clear aligners that have been developed specifically for aligning your teeth in a predictable, smooth, clear and comfortable manner. Instead of metal brackets, wires or screws, you’ll be wearing a thermoplastic material to achieve your desired results – while going unnoticed by the people around you.

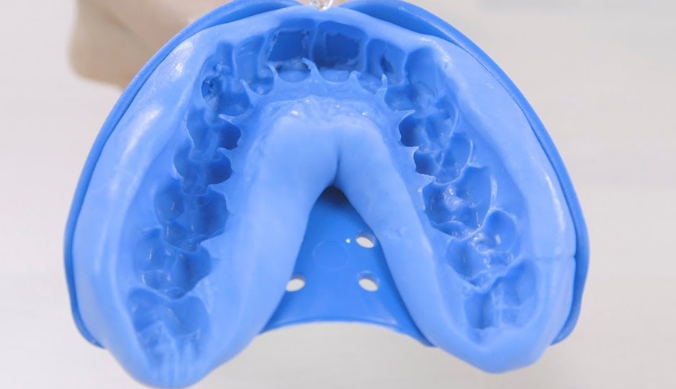

Clear aligners work on basic orthodontic principles. They are used for the correction of crooked teeth, gaps or rotation, while achieving the desired results in an organized and planned fashion. These customized trays are “invisible” and move the tooth in the desired direction. This is achieved through wearing a series of Active Aligners, each for 22 hours a day, 1 to 2 weeks at a time (one stage), which move the teeth per stage until their optimal alignment has been reached.